tehnik

Active Member

Full Member

- Messages

- 521

- Reaction score

- 12

Hi, All!

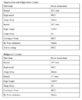

I am having a problem with the Aidite zirconia as bridges longer than 4 units will rock on the model. No matter the design and using the stabilizer. The same files with other zirconia are perfect. Many times it looks like one of the dies is 1mm above the plate, but as said, after milling it from another zirconia it is perfect. I am using programs sent from Aidite and using nabertherm ovens. So far all bridges are deformed and unusable. Aidite send long bridges program with 1450 degrees final temperature and also that is wrong as the material is opaque on such a low temperature (normal 1530). Has anybody else had such an issue with the material and knows a solution?

Best regards.

I am having a problem with the Aidite zirconia as bridges longer than 4 units will rock on the model. No matter the design and using the stabilizer. The same files with other zirconia are perfect. Many times it looks like one of the dies is 1mm above the plate, but as said, after milling it from another zirconia it is perfect. I am using programs sent from Aidite and using nabertherm ovens. So far all bridges are deformed and unusable. Aidite send long bridges program with 1450 degrees final temperature and also that is wrong as the material is opaque on such a low temperature (normal 1530). Has anybody else had such an issue with the material and knows a solution?

Best regards.