brayks

Well-Known Member

Sponsors

Full Member

- Messages

- 805

- Reaction score

- 277

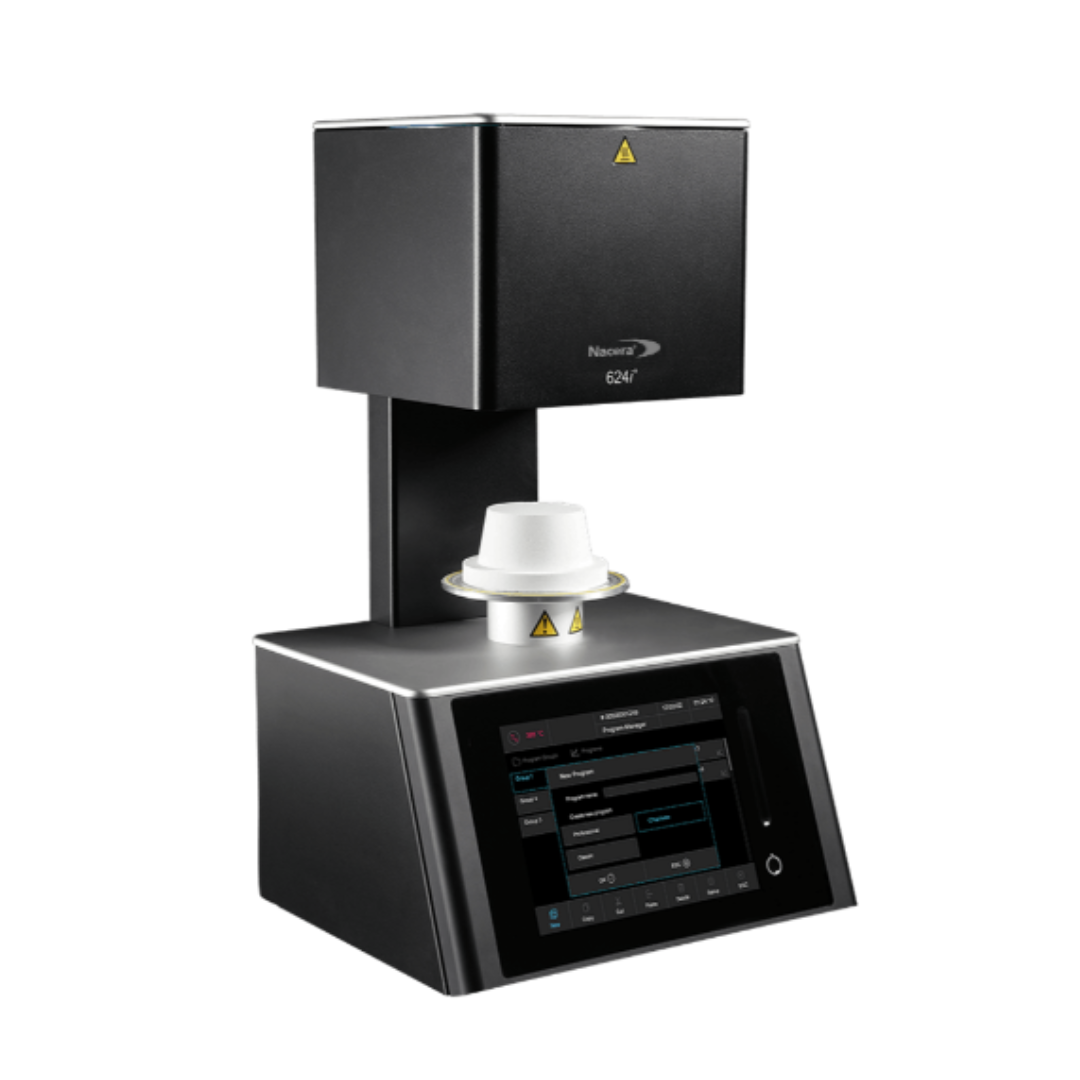

Mihm-Vogt, a leading name in the industry, offers a comprehensive range of sintering furnaces designed to cater to a diverse array of applications and requirements. From small laboratories to large milling centers, their models in various versions and sizes stand out as the ideal complement to any CAD/CAM system.

Precision Programming for Material Flexibility

One of the standout features of Mihm-Vogt sintering furnaces is the ability for users to be flexible in choosing their materials. Unlike being tied to a specific brand, all high-temperature furnaces from Mihm-Vogt can be individually programmed. This flexibility empowers users to experiment with different materials, enhancing the creative and technical aspects of their work.

Time-Efficient Speed Sintering

Mihm-Vogt takes efficiency to the next level with their speed sintering furnaces, which not only save valuable production time but also substantially reduce the sintering process duration. Depending on the material, speed programs consume less energy, contributing to environmental protection and cost reduction for users. The integration of high-quality MoSi2 heating elements ensures durability and reliability, with a programmable temperature range up to 1650 °C, extending up to 1800 °C.

Four-Step Programmable Processes

Mihm-Vogt understands the importance of customization in the sintering process. To cater to diverse needs, their furnaces offer four-step programmable processes. Users have the flexibility to set individual parameters, allowing the use of various sintering materials. The broad temperature range accommodates materials like translucent zirconium oxide, providing extensive possibilities for dental and industrial applications.

Emergency Cooling System for Uninterrupted Operation

In the unpredictable world of technology, power cuts can pose a significant threat to sensitive equipment. Mihm-Vogt addresses this concern with an emergency cooling system featuring off-grid housing cooling. Even in the event of a power cut, the furnace remains protected from overheating. Continuous ventilation ensures that the equipment is sufficiently cooled, preventing any damage at high sintering temperatures.

Tailored Solutions for Varied Needs

Mihm-Vogt offers a range of models, each catering to specific needs. The compact and versatile HT-S sintering furnace is designed for laboratories with limited restorations or those with parallel milling systems. On the other hand, the HT high-temperature furnace is ideal for high workloads in milling centers, offering additional features such as a large-capacity tray and optional second tray, expanding application possibilities.

In conclusion, Mihm-Vogt sintering furnaces stand as a testament to precision, efficiency, and adaptability in the world of dental and industrial technology. Their commitment to providing high-quality equipment with innovative features ensures that users can push the boundaries of what is possible in their respective fields. Explore the world of Mihm-Vogt sintering furnaces and elevate your sintering processes to new heights.

Learn more.

https://cutt.ly/AxsysBlog_Furnaces

Continue reading...