Ken Knapp

Active Member

Full Member

- Messages

- 258

- Reaction score

- 57

Recent 3 unit Noble metal SLM processed bridge does not fit. Individual abutments fit, but does not fit when on bridge.

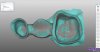

Overlapping images of STL file and scanned bridge shows that #21 moved distal about 150 microns.

SLM process did not reproduce the sent STl file.

I'm 99.5% all ceramic with 99.5% of zirconia bridges fitting. My first SLM bridge does not fit. I have had singles made without any problem.

Is this a common problem with SLM?

I'm going to have the remake made with a cast process instead.

Overlapping images of STL file and scanned bridge shows that #21 moved distal about 150 microns.

SLM process did not reproduce the sent STl file.

I'm 99.5% all ceramic with 99.5% of zirconia bridges fitting. My first SLM bridge does not fit. I have had singles made without any problem.

Is this a common problem with SLM?

I'm going to have the remake made with a cast process instead.

Attachments

Last edited: