I've been using it for over a year now and the machine is working every day cutting ZR without any problems. The advantage of using MDX-50 is that it is cheap, strong and accurate. Half price of DWX50 However, there is a lot of knowledge that must be learned to use it for dental purposes. Especially CAM setup is difficult, at first I managed to do it with the deskproto recommended here, I tried fusion360, but it was too difficult so I went back to deskproto again. PMMA will be cut, but I think it will take a considerable amount of time to get it right. If you want to make a digital denture, I think you will use a 3D printer. Also, the round material holder from the PDI is not suitable for hard materials, the vibration will loosen the screws and the disc will come off. I sell this triple disc holder on EBay for the time being. Please take a look if you are interested.

Thank you for your reply.

I have been printing digital dentures, cast partial frames, models, splints and crowns on my Asiga UV Max for several years already. I found the denture resin is not as good as the one on the disk. I have Dentca just in case if I need to do immediate dentures) I know Dentsply Sirona came with a new Lucitone Digital resin which BAM! technology - a body-activated material. It was only for Carbon printers but now it has approvesd for Asiga and Sprintray. I believe the final announcement is going to be in Chicago in a week.

If you are saying it creates the vibration then the other option to mill the wax bases and flask them with teeth with conventional way but I would like to stay away form that.

I might mill the wax tryin dentures which I could use to checking VD, occlusion, lip support and if any corrections needed doctor can cut or add wax easy in the same time.

Vita has this workflow.

What is the reason for you to sell triple disk holder? Did you switch to the different brand?

I discovered this one long time ago but don't know if it is better then yours.

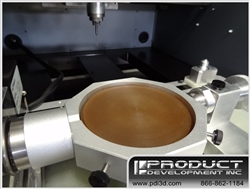

The PDI Round Material Fixture allows you to hold round material on Roland MDX-50 and MDX-540 or other ordinary 4 axis milling machine. The fixture mounts directly to any Roland 4th axis unit. It can also be used directly with any milling system using a 3 or 4 jaw chuck.

www.pdi3d.com

They have an option for single and double fixture systems.

Do you mill zirconia crowns only? How about implant supported restorations? Single full contour crowns over Ti-bases and bridges?

I'm afraid to ask if you tried to mill big bridges. Any pictures to share? How is the machine finishing your margins?

Regarding the CAM. I have someone from my dealer tech support who can connect the MDX-50 to Millbox. I assume if this is a case (and he is able to connect) i can run both MDX-50 and WDX-52D from the same software. I don't have a problem to use deskproto if I absolutely have to.

However I wanted to know the limits and difficulties of using MDX-50.

By the way does it have a suction?

I love when people saying buy "dental" and you will do it right (without headache). If something goes wrong and you don't know how to fix it or what to do- it does' matter if it is branded "dental" or not. Meanwhile most of it came to the dental manufacturing from the other industries and adapted for our needs. Yes, if person can't figure our things it is better to use "1,2,3" steps to work. But if the hardware is not capable to do the job, it is the different story.

3D printing rapidly came to our dental life and many of us learned form inexpensive printers / materials many years ago. They were not dental and we learned why and how to use them for our needs. Now, the same companies are promoting newer models of their printers as "dental" They all learned from us too! Thanks to all enthusiasts who spend their time to figure out how to adapt things for dental use.