Mona Lobsey

Member

Full Member

- Messages

- 54

- Reaction score

- 1

Could be a bur problem. But looks more like a CNC issue. However, when I was working in a lab that brought in a Brand New Imes Icore 340i. We were chipping and destroying framework left and right, right outa the box. The last thing we changed was getting rid of the burs that came with the mill and using a new set from sagemax. Problem was solved after this.What the hell is this! My Imes icore machine is only 6 months old and i am using their burs! The burs are new and they cut only 26 crowns! What do you think?

Imes Icore 450i, It was perfect in the beginning. Do you think there is a problem in the strategy? I have a new technician who is handling it, what could be wrong with the strategy that its milling too fast?what CAM are you using? Looks likes its cutting way too rough.. too fast.. Who made the strategy?

several waysImes Icore 450i, It was perfect in the beginning. Do you think there is a problem in the strategy? I have a new technician who is handling it, what could be wrong with the strategy that its milling too fast?

II would suggest to mill a test coping from the control software (all sides should be 0.5mm)

- If the test copings are fine it's most likely a CAM issue (check federates, step increments etc).

- If the test copings are not OK it's most likely a machine issue (make sure the machine is leveled and all axis's calibrated)

Hi Mona,

Run the machine with a tool and see if there vibration on the tool ...

Apply a thin metal rod on the tool when it turns to feel the vibrations ....

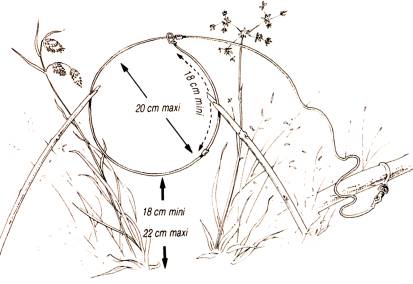

If you have vibrations, try to change the "clamping claw" (?) not sure of translate , one pic ,

I had this problem after 6 months of use ....

good luck !

I

Thanks! Yes THAT IS THE PROBLEM! I cleaned the Collet and everything is perfect again! I live and learn about this machine but obviously i will get lot of heart attacks till then!