DMC

Banned

- Messages

- 6,378

- Reaction score

- 260

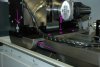

Anyone familar with G93 inverse time command to use before any 5-axis continious motions? (G94 turns this off)

Also, I have questions about the setting in my CNC controller for the diameter of 4th/5th axis.

The diameter of rotary table that spins 360 (my B-axis or my 5th axis) is making my brain fry....

The tilting axis diameter (my A-axis or 4th axis) makes total sense to me. I measure from centerline of the tilting axis going away from that to the center of my workoffset.

Scott

Also, I have questions about the setting in my CNC controller for the diameter of 4th/5th axis.

The diameter of rotary table that spins 360 (my B-axis or my 5th axis) is making my brain fry....

The tilting axis diameter (my A-axis or 4th axis) makes total sense to me. I measure from centerline of the tilting axis going away from that to the center of my workoffset.

Scott