rkm rdt

Well-Known Member

Full Member

- Messages

- 21,460

- Reaction score

- 3,288

Solved...next problem?

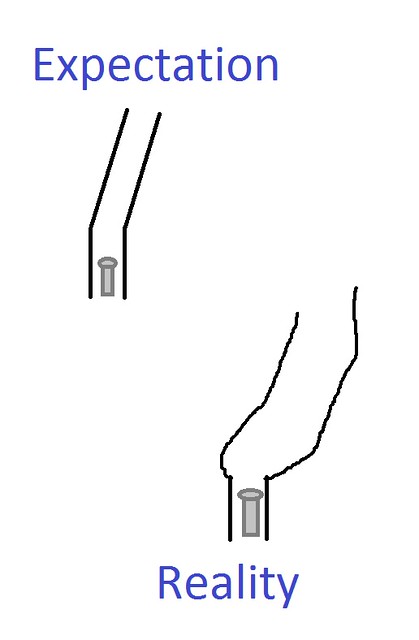

Well I've seen a lot of cases where the Doc requests a screw retained restoration, but after informing them that the screw channel on an anterior comes straight through the facial, they no longer get what they originally wanted.

This application may be usefull for me in the future. In fact I have a case in front of me we did a cemantable restoration on but the doc originally wanted a screw retained anterior. Just couldn't do it. I would just need someone to mill me an angled anotomical abutment, and yes a zirc interface. I know I know, but doctors orders, oh well...

What fixture is it Marc?

I hear you John, I get the 3.0 blues as well.

I sure wish they made ti bases for these.

As I see it, it is physically impossible and still emerge from the fixture. The width of the head of the screw along with the width of the ti insert along with the outside wall diameter of the Zirconia will not allow a sub 3.2mm emergence. Now with that said using a stock abutment cutting it down and glueing it in can be done but look at the emergence, looks ugly.

Ever wonder why the screws are so damn tiny and the torque settings are so low for those fragile screws even for stock abutments?

Even on NP fixtures larger than 3.5mm I feel I am reverse platform shifting with cad bases.

The only solution would be a new material to make the screw out of ( higher strength) with a total revamp of the tooling required to torque.

I just don't see that happening.

Cool, cut it in half and show me the screw channel!

Thanks in advance....

I tried emailing both companies and have not received any response. Talladium doesnt support the system anymore, I was told staffing issues. I did a duralay mock up on the case today and I will only need a couple of degrees to fully clear the incisal edge so I may encourage a nt trading 2-connect style hybrid.....I will see about screw availability if Scotty wants to try it. I did notice the diameter of the screw head is much smaller than most based on the thread diameter. This would not only support the lolly pop theory but also make the access channel slightly more familiar in size, the driver is just a micro rendition of what we all have in our garages for driving allen head bolts from an angle.

Well I've seen a lot of cases where the Doc requests a screw retained restoration, but after informing them that the screw channel on an anterior comes straight through the facial, they no longer get what they originally wanted.

This application may be usefull for me in the future. In fact I have a case in front of me we did a cemantable restoration on but the doc originally wanted a screw retained anterior. Just couldn't do it. I would just need someone to mill me an angled anotomical abutment, and yes a zirc interface. I know I know, but doctors orders, oh well...

I send everything to Atlantis. And receive an additional screw for an arm and a leg. The new screw gets stapled onto the original RX and sent back to the doc. Would be nice if Atlantis offered lab screws...We have been experimenting with milling One-piece Zr abutments recently.

They look and fit great.

We even have done them in multiple colors with Pink below Ginviva and any color you want on top.

Working on angled channel this coming week. It is totally possible!

You ever seen these before? Probably looking at $59, plus design time, and you tell Doc to go get a NEW, real screw from manufacture. (Or you buy it for him:?) I don't like providing screws because we don't want labs using them, then passing-off to Doc a used screw.

When Doc buys his own screws, then he should know exactly what driver to use and what torq-spec, also knows that it is clean and un-used. I think this is best.

Or stripping the head of the hex, then you are really screwed. Easier to getIt will rattle down to the bottom. No problem.

Doc may have more chance of cross-threading the screw! WHOOPS!

Solved...next problem?

I worked for Jim GL many years ago. So I called some old coworkers and inquired about an assortment of screws so I could just keep them layin around in the lab and use instead of the final screws. They never got back to me, so screw em. pun intendedWe have screws also....$10. They are just from Glidwell, and I buy $4k worth of implant stuff from them at a time to reduce cost.

But I prefer to have Doc know what he is doing and get in habit of keeping them in stock in his office.