Simon_Vincismile

Member

Full Member

- Messages

- 52

- Reaction score

- 0

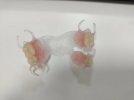

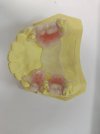

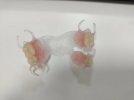

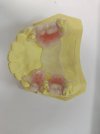

Hi, everyone. I have a try to make a removable partial with our flexible framework. It is my first time to make it so I'd like to know if you have any suggestions about it.

I design the framework and then milled it from the flexible disc. Polish and then flask, just like what I do to make the partials with metal.

I'm not sure what the patients feel about it. Maybe it is not nice enough, but I think it looks good for a beginner.

Look forward to your suggestions. It would help me make better flexible partials!

I design the framework and then milled it from the flexible disc. Polish and then flask, just like what I do to make the partials with metal.

I'm not sure what the patients feel about it. Maybe it is not nice enough, but I think it looks good for a beginner.

Look forward to your suggestions. It would help me make better flexible partials!