lcmlabforum

Well-Known Member

Full Member

- Messages

- 1,476

- Reaction score

- 160

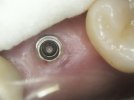

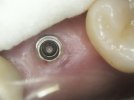

Interesting case thought I best share . . .

This was pt from last week, glad took a good look and noticed after second look/cleaning debris below - pt had new screw placed just Jan 2022

Fortunately, I took pictures in Jan 2022 also . . . and pt not upset once he saw this because he also knows I insist on ordering original implant manufacturer parts.

Maybe Darwin or some others working with manufacturers can chime in - Quality control issue or design flaw?

LCM

This was pt from last week, glad took a good look and noticed after second look/cleaning debris below - pt had new screw placed just Jan 2022

Fortunately, I took pictures in Jan 2022 also . . . and pt not upset once he saw this because he also knows I insist on ordering original implant manufacturer parts.

Maybe Darwin or some others working with manufacturers can chime in - Quality control issue or design flaw?

LCM

!

!