RDA

Well-Known Member

Full Member

- Messages

- 947

- Reaction score

- 192

Looking for recommendations on plastic tweezers/hemostats, or rubber tipped tweezers/hemostats for holding green state zirconia. Possibly something that locks.

im using plastic college pliers from Nowak. tips are a bit large and bulky but trimming them down was easy.Looking for recommendations on plastic tweezers/hemostats, or rubber tipped tweezers/hemostats for holding green state zirconia. Possibly something that locks.

8 pack for 3.50 https://www.sciplus.com/plastic-tweezers-42002-p

8 pack for 3.25 https://www.sciplus.com/loopend-tweezers-48709-p

hole about 9/16 by 3/8 so you can cradle instead of squeeze.

Plus, their catalog is hillarious.

Agreed.A lot cheaper than getting them from ADS

I like these (from your web page link) for using at the steamer in holding crowns a little more securely, more ridged: https://www.sciplus.com/curved-forceps-54066-p

What type of baskets?Why not just use (non latex if needed) gloves? Nothing works better than my fingers.

For dipping, I use baskets or cheap yellow plastic tweezers from ADS to retrieve the crowns out of the jar.

https://www.americandentalsupply.net/store/product.php/664.htm

thats why i left that lab. i got feedback things were wrong but i was tightly controlled to NOT modify the CAM or machines for fear of voided warranties and broken machines. so fine you get crowns with wrong bites and thats the and of the story.Luke if you don't do the finishing of the final crown how could you possibly know what you designed/ milled is perfect?

What type of baskets?

want to come tweak things?thats why i left that lab. i got feedback things were wrong but i was tightly controlled to NOT modify the CAM or machines for fear of voided warranties and broken machines. so fine you get crowns with wrong bites and thats the and of the story.

what i can now prove beyond reasonable doubt is that the CAM is the biggest source of problems for people doing CADCAM. its a little field of data science called Metrology. download free Metrology software for most purposes on a free restricted Trial basis if you like.

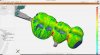

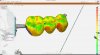

here is a Metrology scan of a bridge, the dark blue is the edges of the designed bridge, while red and yellow and Green areas indicate how off the mill made it. we are comparing a scan of the milled bridge, to the CAD, 3 different tries at the same file.

View attachment 31085 View attachment 31086 View attachment 31087

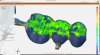

now, after modifying only the CAM parameters i was able to make that same bridge to this tolderance:

View attachment 31088

this bridge is now perfectly milled to my design.

thats how i know how off it is even before the ceramists judge design and grind the heck out of it for funsies anyway.

i use them, they work great. still need tweezers (plastic) but these jars are great

when we roll out our secret sauce to the world i won't need to come to you to tweak things. if you simply mill a file, scan it, send the design and the scan of the product to me, i'll be able to fix you remotely.want to come tweak things?

ETA?when we roll out our secret sauce to the world i won't need to come to you to tweak things. if you simply mill a file, scan it, send the design and the scan of the product to me, i'll be able to fix you remotely.

because i would need 6 months with any other CAM software to make it do what i want.

trust me when i say this is part of the plan.