Roland DWX-50: DRY

ZR

PMMA

WAX

nanocomposites (If you have the proper tools and holder for the blocks, it is the same holder as e-max cad)

VHF 5axis: DRY/WET

ZR

PMMA

WAX

nanocomposites

glass ceramics

CrCo

Ti

DWX-50:

Belt Driven (everything including spindle)

Doesn't come with CAM software

Spindle can't provide a lot of torque (Brushless DC motor, maximum 100W)

External size 25.9 x 25.9 x 22

Built in Japan

6 tools MAX in holder

Weight 50kg

max disk height 98/100mm x 26mm with levels on disk 98/100mm x 20mm without levels on disk (center level ring 10mm)

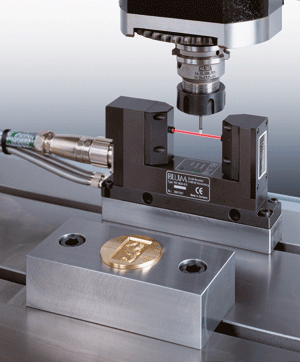

mechanical touch off

Rotary Axis A: +/-360 degrees, B: +/-20 degrees

VHF 5Axis:

Screw Driven

Come with CAM

Jager Spindle, air driven much more torque provided

Will out Mill the Roland in life span

External size 5-S 20x18x21 no disk changer / 5-S2 27x18x21 with 8 disk auto changer

Built in Germany

16 tool in holder

Weight 75kg 5-s / 95kg 5-s2

Max disk height 98mm x 30mm

mechanical touch off

Rotary Axis A: +/-360 degrees, B: +/-30 degrees

Repetition accuracy +/- 0.003mm

Both will cut the same, the VFH will be slightly more accurate due to screw drive train. Imagine the VHF as a uber small version of the iMes iCore machines, they are built the same but on a smaller scale. The iMes iCore machine are built to cut CrCo and Ti for a much longer span of time, but the VHF 5axis wet mill will cut CrCo and Ti but not really meant for long cutting times like a full disk worth repeatedly. I have two VHF 4axis mills and they are work horses, one is running the v4 cam software and the other is running the v5 software, the software that is going to be on the 5axis wet mill. Yes I have issues running certain burs on the v4 mill and have stuck to cutting only wax and use the sierra razor sharp burs only and never change them. My V5 mill can run the sierra diamond coated burs both 1mm and 2mm with no issues, the mill have the upgraded current chip for the electronic touch off. The major issue with my V4 mill that I made a huge fuss over on here.

But the newer 5axis mill has the mechanical touch off like the DWX-50 so no more tool crashing due to un-compatible tools. in the end they both will give you the result you are looking for. If you want to cut a fewabutments in house and don't have the money or the room for the Imes 450i or Datron D5 the the new VHF 5 axis mill is going to the right mill for you. The DWX-50 is a great mill for ZR/WAX & PMMA but your done right there. The VHF 5-S/5-S2 gives your much more milling options a better built mill and a CAM software that is more then enough for most of the labs that purchase the machines and have no clue on the depths of CAM software. I can CAM a full disk of ZR or WAX in less then 15min and have the mill start cutting on the V4 software but the newer V5 software I need to let the CAM get the fist 1/3 processed before starting the mill. Sum3D for the DWX-50 can either be a easy 1-2-3 process or open it up and have all the options play around and mess things up if you have no clue what your doing, it is a good piece of software but once again for most labs that purchase it, it is way too much cam and they barely use a fraction of it's power.

This is my experience cause I have personally worked on a DWX-50, iMes iCore 340i and the VHF 4Axis miss, the 5Axid is going to be launched very soon. We will pick up on of the VHF-5-S or 5-S2 once available and now have three mills in operation, 2 x 4 axis and one 5 axis.

DWX-50 specs VHF-5-S/5-S2 specs Sevan