J

jasperjo

New Member

- Messages

- 1

- Reaction score

- 0

I hoping to obtain some tips here for casting gold abutments.

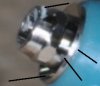

Once in a while when casting the Straumann Synocta gold abutments we get gold runing onto the fitting surface and it will vary from a light layer to a rough surface tiny spicules covering a large areas of the surface. We use the same procedure for other systems like Nobel replace and active and never have problems only these synoctas. Is it the design of their gold cylinders that is the prob.

no debubblelizer is ever used

we use Deguvest F investment

Burn out to 1000 C and then lowered to 850C for torch cast and not electric

Once in a while when casting the Straumann Synocta gold abutments we get gold runing onto the fitting surface and it will vary from a light layer to a rough surface tiny spicules covering a large areas of the surface. We use the same procedure for other systems like Nobel replace and active and never have problems only these synoctas. Is it the design of their gold cylinders that is the prob.

no debubblelizer is ever used

we use Deguvest F investment

Burn out to 1000 C and then lowered to 850C for torch cast and not electric